Coilers

For Winding Small Coils of Wire, Cable, Hose and Conduit

Coilers are used for production winding of small coils of wire, cable, hose or conduit onto spools, reels, or collapsible heads. Product lengths are generally less than 1000′. They can be operated individually or automatically controlled as auxiliary equipment in a process line, and can be operated in either speed or torque mode. Calmecs Dual Coilers are multi-head machines that are used in a continuous process, such as armoring, and have traverse wound, cut-to-length and length measurement capabilities. They provide the utmost flexibility for both winding and processing, and can accept reels or spools up to 36” in diameter.

- Single and multiple head machines

- Operated individually or with automatic control

- Shaft type for reels or collapsible heads for coils

- For continuous process or stand alone applications

- Optional integrated length measurement, traverse wound, cable clamping, breaking rollers, and cut-to-length

- Operating in speed or torque modes with AC vector or servo motor drive options

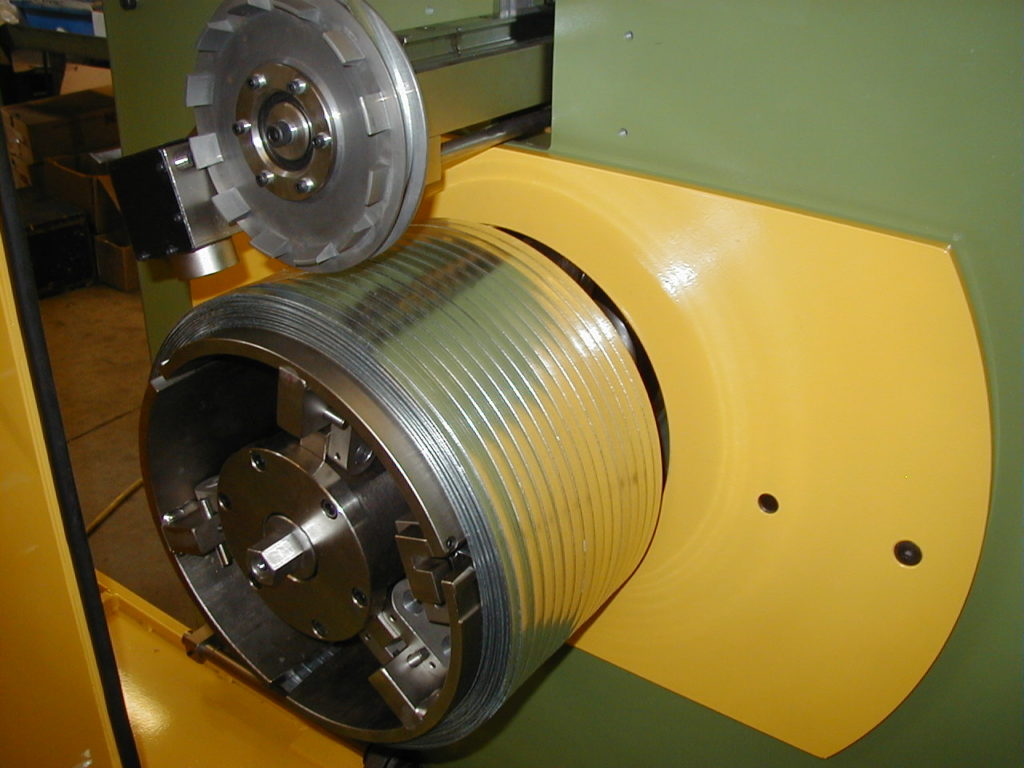

Collapsible Heads

Calmec can supply heads to suit products from 1/4″ to 1 1/2” diameter. All heads are width adjustable from 2″ – 8 “, with minimum coil cores as small as 7” diameter. Collapsible heads are also quick change removable. Quick change shafts result in easy changeover for spools or reels.

Multiple Drive Alternatives

All machines can be supplied with AC vector or servo drive alternatives, and can operate in either speed or torque mode, whether operated individually or speed synchronized to a line process. Dancers for trimming the line speed reference can be integrated as well.

Product Build Up Compensation

In some cases it is important to maintain consistent product tension during the coil winding process. Calmec achieves this on its Coil Winders by incorporating PLC based winding compensation software.

Traversing

An electronic ratio controller provides a consistent and accurate lay on Coilers where traversing is required. The operator need only input the product diameter; the traverse speed is synchronized to the incoming line speed.

Auto Loading And Unloading Of Reels

Dual Coiler’s for large diameter reels or spools can be automatically loaded and unloaded from and to the ground. This removes the need for additional lifting equipment and further automates the process.

Dual Coilers

Included features on multiple head coiling machines are length measuring, a pneumatic cutter, cable clamp, and traversing of a guide sheave for traverse wound packages. Machines are available for maximum 24”, 30” and 36” reel diameters.