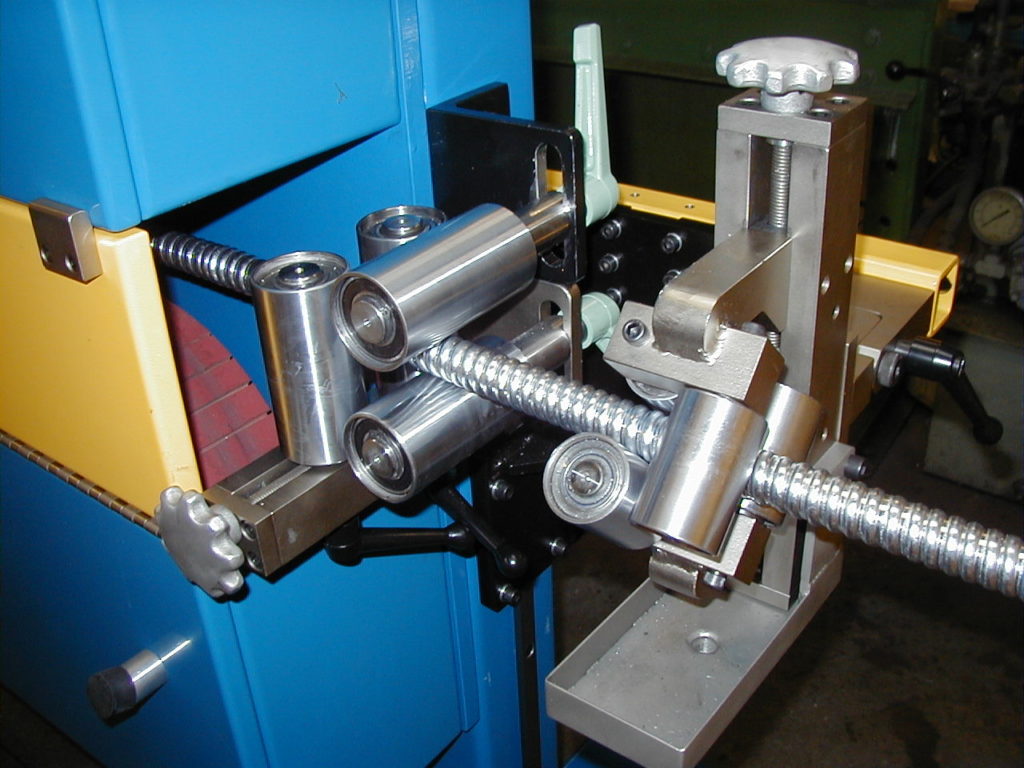

Cater Pullers - Capstans - Tensioners

For consistent pull-through of wire & cable, hose and conduit

• For wire, cables, conduit, hose, metals & plastics

• Pull a wide variety of flat or round product

• Up to 1/4″ diameter wires on Tensioners, 1-1/2” diameter products on Capstans, and up to 6” diameter products on Cater Pullers

• Variety of styles, sizes, line speeds ft belts to suit your application

• Stand-alone controls or remote line control

What belt is best for your application?

Calmec provides a variety of belts to suit your application. Determining factors include the type of product being pulled through the machine, the required process, and line speed. Choosing the correct belt is most important, as it affects the quality of pull, the amount of belt wear, and cost.

AC Flux Vector & Servo

All Calmec machines use AC flux vector or servo drive technology, comprising of AC flux vector or servo motors and drive controllers for precise electronic synchronization. This replaces traditional differential gearboxes and variators, as well as higher maintenance DC motor drives.

Optional Servo drive packages are also available, for the highest degree of drive stability and the fastest machine acceleration and deceleration speeds.

Pneumatic Compression & Tension

Calmec uses multiple air cushions to provide consistent pressure on the product as it travels through a Cater Puller. Air cushions provide belt compression as well as belt tension, and are pressure adjustable to suit the style of belt used and the type of product being pulled through.

Ratio Display Scaling

Depending on the type of product being run through the machine, Calmec can provide an electronically geared ratio display to suit the application rather than just displaying a value with no meaning. For example, if conduit or armored cable is pulled through, we can display convolutions per foot/meter of product as the adjustable ratio affecting the line speed.