For the continuous non-rotational production of square locked and fully interlocked flexible metal conduits.

- Single strip (CT1C) production lines

- True triple drive system; AC vector or servo motor controlled

- Tooling heads for both 2 and 3 sets of form rollers, dependent on profiles required

- Tooling heads balanced at every fixed angle position for maximum operational speeds

- Nominal 2”, and 4” machine sizes

- Aluminum, steel, and stainless steel materials

- 3/8” to 3/4” wide strip, with maximum pad weights up to 1,500 lbs.

- For traverse wound strip coils; 6”, 9” and 12” nominal widths

- Electric strip tensioning system with automatic self-adjustment; no wear items

- Pneumatic coil chucking

- Colour touch screen process setup and control

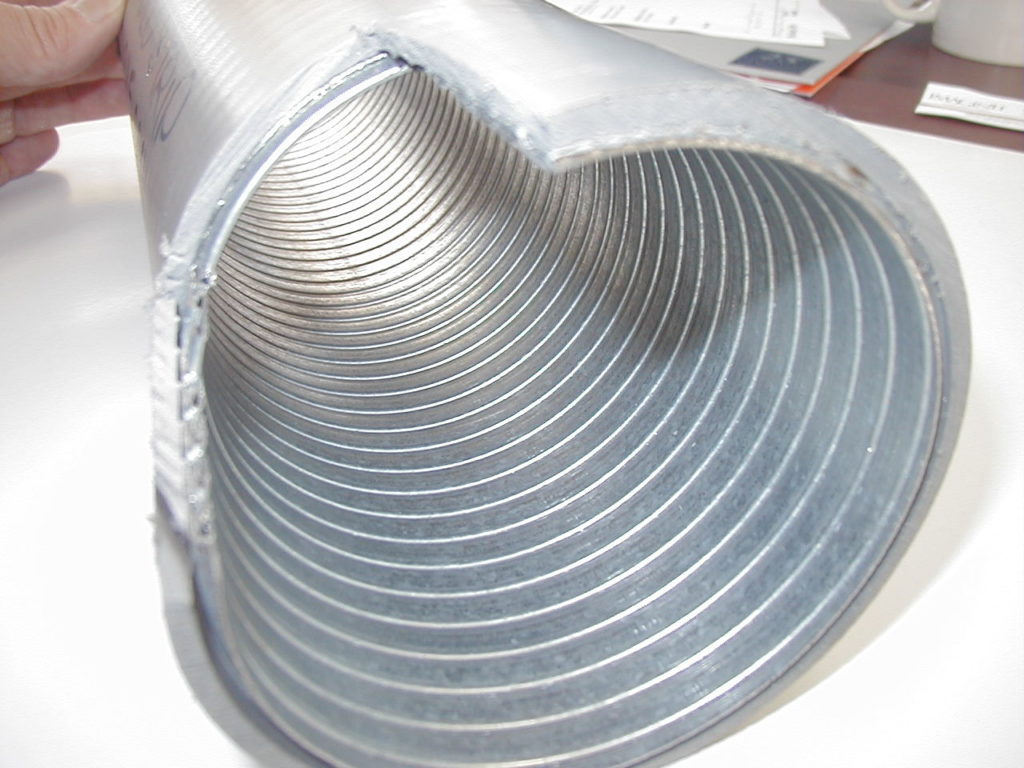

Calmec CT1C Conduit Machines are designed for the continuous production of square locked and fully interlocked flexible metal conduits. They produce round conduit for use with cables, hoses, and deep sea umbilicals for offshore oil applications.

The strip is formed to the desired profile and helically wrapped around a mandrel using multiple compression rollers. Tooling heads are balanced at fixed incremental angles for maximum machine speed capability; the head angle is reduced as the product size increases. The menu driven touch screen provides all setup information required.

Key Features

- Head assembly designed for positive and fast tool changeover

- Multiple fixed head angles with balanced positions provide optimum positive placement and higher running speeds at all head angles

- True vector AC vector or servo motor drive system reduces maintenance by eliminating high wear mechanical gearbox, or variator

- Hardened tooling throughout for longer wear

- Off-line tooling setups

- Multiple profiles and strip configurations available

- Menu driven colour touch screen for full product range, with recipe specific parameters & tooling requirements, display of system parameters, and maintenance screens

- Low coil detection based on strip feed rate; no sensor

- LED lighting throughout

- Optional Breaking Roller Assemblies for adjusting product flexibility

Multiple Motor Drive System

- Four independent AC vector or optional servo motors; one for the main spindle, for the strip feed, for strip tensioning, and for the Cater Puller

- True full motor system, no differential or gear box required; drives digitally synchronized

- Multiple drives eliminate the mechanical variator, PIV, or differential and all the associated mechanical maintenance issues

- Digital drives allow for repeatable, precise and accurate menu set-ups

- Drives can also operate independently for set-up purposes, meaning the strip feed rolls can be run while the tooling head remains stationary; a safer and efficient tooling setup

- Electrical control of strip feed rate with digital setting and display